Process

This understanding has translated into a tailored customer experience from initial design assistance through production and build support.

DESIGN ASSIST COLLABORATION

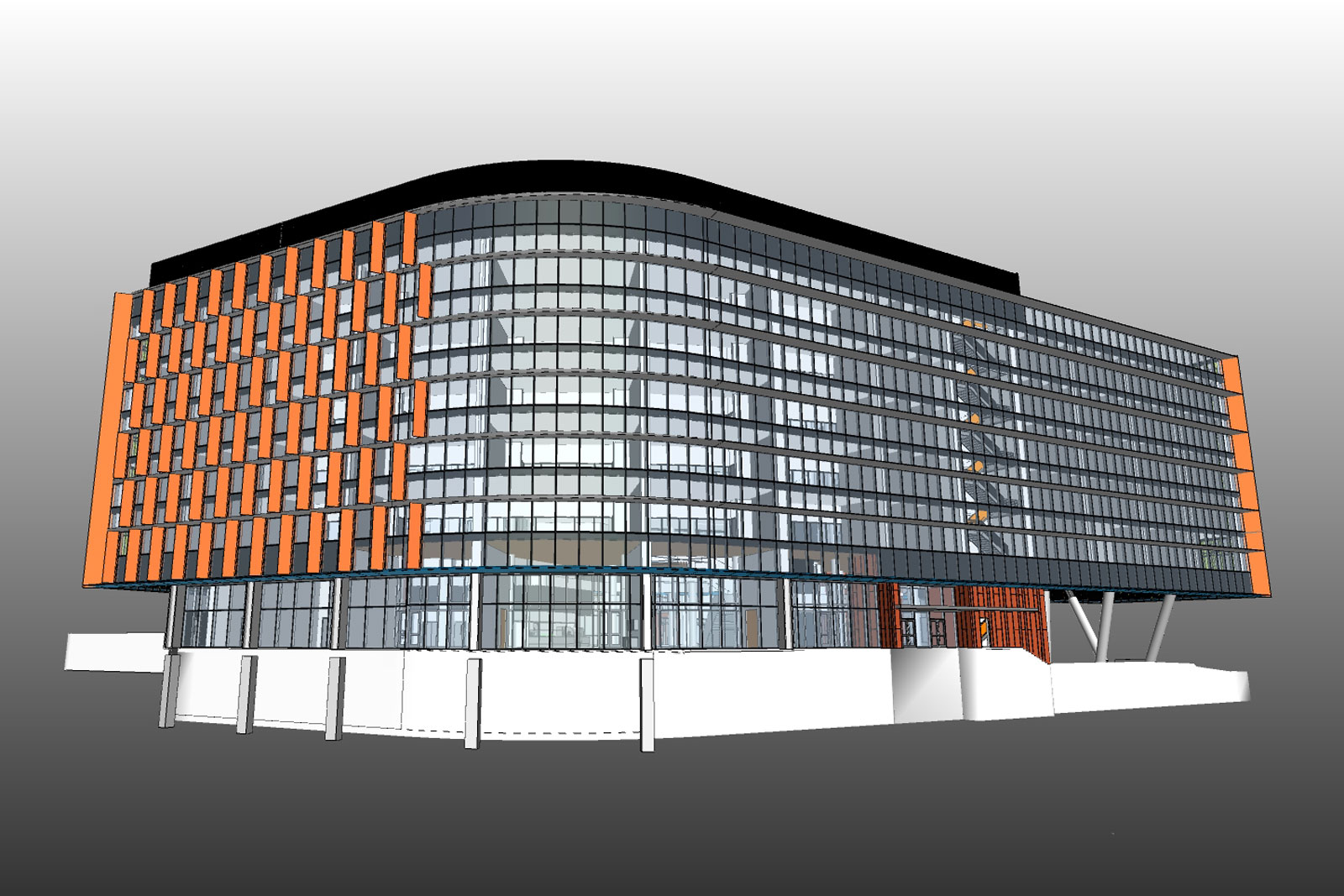

The Design Assist management method has been proven to mitigate risk inherent to unique and complex building developments. Erie has embraced the Design Assist methodology and placed it at the core of our project development process by providing services such as development of system drawings, preliminary calculations and loads, preliminary thermal modeling, project budgeting, valued-engineering explorations, photo-realistic concept renderings, and high-fidelity 3D digital and printed models.

FACADE ENGINEERING

Our in-house engineering team is led by accredited Professional Engineers with the ability to stamp work in major markets across the United States. Our engineering team is comprised of structural engineers, applications specialists, and product developers, offering a variety of services including architectural drawing submissions, production drawings, BIM, concept research, and calculations pertaining to structural, thermal, and blast loads.

PERFORMANCE VALIDATION

Erie has developed an on-site technology center where we have the freedom to construct full-scale visual and performance mock-ups as part of the formal performance evaluation of a facade, or as an internal research and development initiative. Our technology center analyzes facades on the principles of static and dynamic water infiltration, structural loads, vertical and horizontal movements, thermal cycling, impact cycling, among other parameters, utilizing the latest testing instrumentation which is calibrated and certified by a national accredited third-party testing agency.

STATE-OF-THE-ART MANUFACTURING

Erie has invested in a state-of-the-art onsite manufacturing operation that houses all of its curtain wall production. Our facility has incorporated the latest production and machining technology enabling us to handle high volume and highly complex facade designs which are all produced based on BIM planning. By maintaining dedicated technical staff onsite at our production facility, we are able to closely monitor the quality control operations which are led by a Professional Engineer, ensuring our ENVIRO|FACADES® products are all up to the high standards the company has established.

TECHNICAL SUPPORT

We value our partnerships with glazing contractors and strive to achieve effective chains of communication by providing a high level of transparency in our operations as well as attentive customer service. Erie has established an experienced team of technical staff that are a fundamental contributor to its success in delivering projects that are on time and on budget. We proactively track our products through the install process offering technical assistance and design validation in the field.